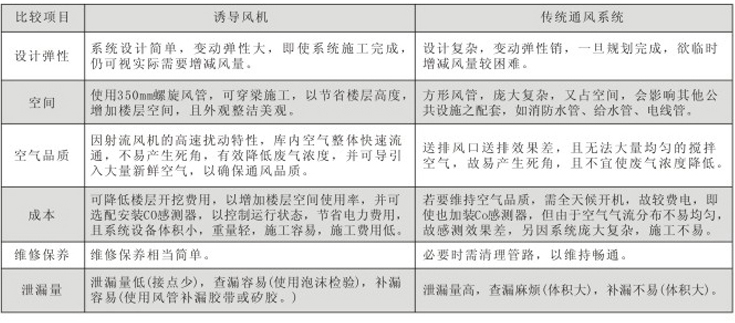

Product Specifications

Features: Simple design, flexibility, space-saving, convenient installation, high efficiency and energy saving, easy maintenance, high quality, new-type nozzle, manually adjustable direction.

Uses: Widely applied in underground parking lots, gymnasiums, exhibition halls, indoor swimming pools, airport halls, various warehouses, supermarkets, and large industrial enterprises.

Specifications: Including YDF-A type and YDF-B type

Ventilator diameter: Φ250~280mm,

Air volume: YDF-A 3600~6000m³/h,

YDF-B 630~850m³/h

Product Overview

Induction fans adopting the concept of jet induction ventilation systems are composed of supply fans, multiple induction fans (or duct-type induction fans), and exhaust fans. The core theory mainly originates from aerodynamics, where the disturbance characteristics of a small amount of high-speed jet gas effectively induce the surrounding static air, driving air circulation. Without air ducts, according to the law of momentum conservation: the central velocity of the jet gradually decreases from the outlet point, while the jet width gradually increases, and the amount of induced surrounding air also increases progressively. Based on this principle, fresh air is induced and sent to the second fan (nozzle) installed within the effective range of the first one. This process repeats, delivering fresh air to the required areas, which is finally exhausted outdoors by the exhaust fan. Through appropriate system design and layout, it realizes optimal indoor air distribution, achieving efficient and economical ventilation effects.

Traditional underground garage ventilation systems use low-speed air duct supply and exhaust systems arranged inside the garage, which have the following disadvantages: large duct cross-sectional dimensions, gas often accumulating in dead corners far from the air flow, a oppressive feeling due to the generally low net height of garages when using low-speed ducts, high installation workload and investment, high operation costs. Additionally, in some buildings, air ducts cannot be installed at all due to their structural characteristics.

Induction fans have become widely used ventilation equipment in large spaces such as parking lots, various warehouses, stadiums, and workshops in industrialized countries like Europe, America, and Japan. This ventilation equipment has been adopted as a conventional ventilation method for underground parking lots and incorporated into building equipment design codes, gradually being promoted and popularized.

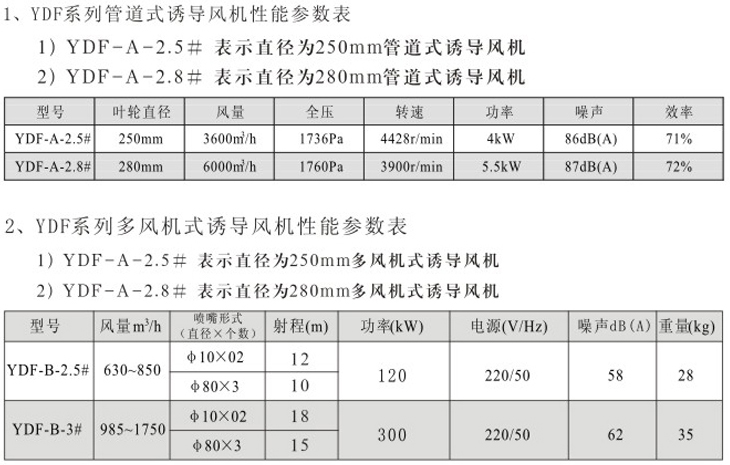

Product Parameters and Description

1)Calculate the floor area and ventilation volume first: According to Article 139 of Chapter 5 in the Construction Design and Construction Section of the Building Technical Regulations, the standard air exchange volume is 35 m³/h·m².

2)Install appropriate numbers of exhaust fans at the air supply and exhaust outlets (the total air volume of supply fans or exhaust fans equals Q), where supply fans provide fresh air and exhaust fans remove waste gas.

3)Install high-pressure fans and nozzles appropriately: Arrange 1 duct-type fan for every 1,000 m² area, and install 1 nozzle for every 30 m² area. Each high-pressure fan can supply approximately 30 nozzles. Place the high-pressure fan in a certain location, then distribute the nozzles roughly evenly, noting that they should be arranged toward the outlet.

4)Connect high-pressure fans and nozzles with high-speed spiral air ducts. The main pipe shall be 35 cm in diameter, and branch pipes shall gradually decrease to appropriate diameters and pass through beams.

2. Air Volume Design for YDF Series Multi-Fan Induction Fans

1)Determine the air volume according to the specification that the underground garage shall have an air exchange rate of not less than 6 times/hour: Q > 6·V m³/h.

2)Select appropriate supply and exhaust fans at the air supply and exhaust outlets.

3)Determine the number of units based on the principle that one jet unit can cover 100–250 m². Take the upper limit when the garage area is small with few obstacles like partitions, and take the lower limit when the garage area is large with many obstacles.

4)Arrange the units according to the determined number and the building form, with the principle that air flows smoothly from the inlet to the outlet.

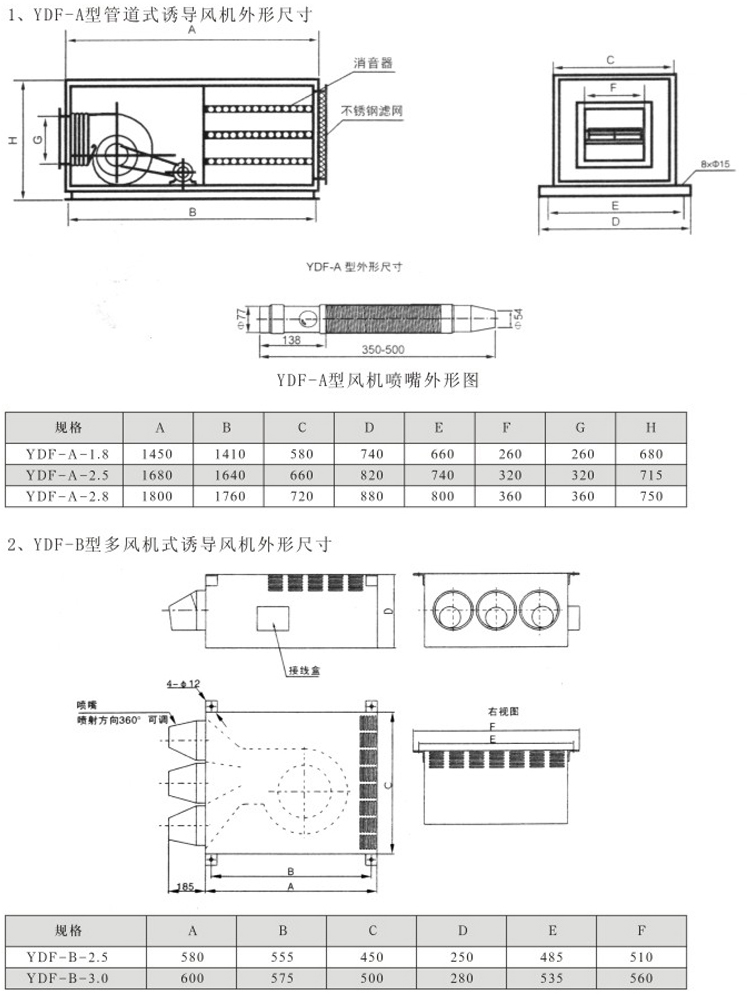

3. Downward Angle of Nozzle (H = height from nozzle to ground)

H < 2.5 m: A = 0°

H = 2.5–3.0 m: A = 15°

H = 3.0–4.0 m: A = 20°

H = 4.0–4.5 m: A = 30°

4. Design Specifications

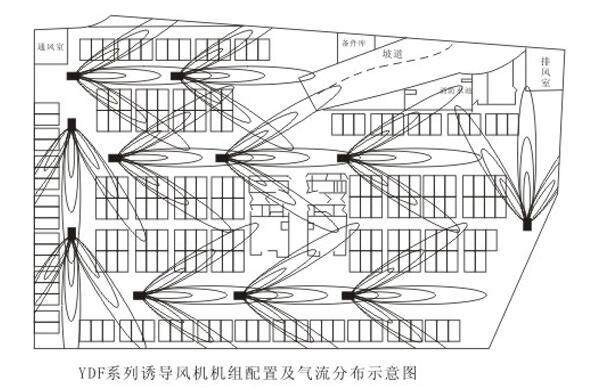

1)The jet guidance system consists of three parts: supply fan, induction fan unit, and exhaust fan. The supply fan provides fresh air; the induction fan unit mixes the air in the garage evenly, induces fresh air from the supply outlet to the exhaust outlet along the designed path, and drives waste gas to the exhaust fan; the exhaust fan then discharges waste gas outdoors.

2)The positions of supply and exhaust fans should be set at both ends of the fire compartment.

3)In a fire compartment with car entrances/exits directly leading to the outdoors, supply fans may not be installed.

4)Underground garages with an area not exceeding 2,000 m² may not require a mechanical smoke exhaust system. For non-compound garages with automatic fire extinguishing systems, the floor area of a fire compartment can reach 4,000 m².

5)For smoke exhaust ducts, since they no longer serve as exhaust ducts, the air velocity in the ducts can be increased to 20 m/s, and the coverage distance of each smoke exhaust outlet can reach 30 m. This ultimately reduces the size and density of smoke exhaust ducts significantly (generally by 50%) compared to conventional practices. Additionally, as the spacing between ducts is extended, smoke exhaust ducts can often be arranged along the walls around the garage or other locations that do not occupy the garage's floor height.

Life experience tells us that if the air in a fixed space is polluted, the way to ventilate is to form air convection, commonly known as the "crosswind". The crosswind can thoroughly replace the gas in the fixed space within a short time.

Similarly, to achieve rapid ventilation in an underground garage or a larger space, a "crosswind" is also needed. However, due to the 特殊性 (special nature) of such scenarios, natural crosswind cannot be relied on for ventilation. Induction ventilation equipment precisely realizes the artificial creation of "crosswind".

Its core principle is using the law of conservation of momentum: a wind speed with certain energy is ejected at high speed, gradually diffusing into a "wind surface". These artificial "wind surfaces" are arranged like a wall, advancing along a set path and carrying polluted air along the way to a designated location. Since wind has an indeterminate shape, it can adapt to various cross-sectional changes during movement, resembling a piston filling the entire space and moving forward along the walls. The theoretical air exchange efficiency reaches 100%. This ventilation method is called "displacement" or "through-flow" air exchange.

Induction ventilation equipment is the key to realizing artificial crosswind. Thanks to its high air exchange efficiency, this technology, which originated in Europe and America, has been applied for nearly 20 years. In recent years, it has gradually been accepted and adopted by many domestic users and professional technicians. In 1999, the Beijing Institute of Architectural Design included this system and equipment in Technical Specifications for Architectural Equipment Design, Chapter 3, Section 6.4. The measures clearly state: Mechanical ventilation in parking garages should preferably adopt jet-induced ventilation to ensure good air exchange, while reducing duct costs and the floor height occupied by garage equipment.

The purpose of intelligent control for induction fans is to achieve effective energy conservation and prevent malfunctions, ensuring the safer, more reliable, and economical operation of the induction exhaust system. Additionally, it aims to enhance the overall intelligence level of the building.

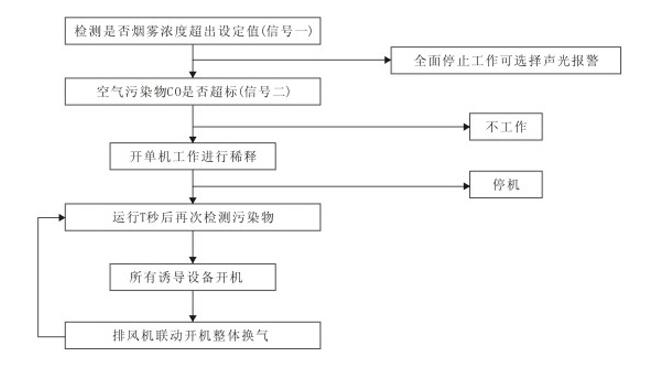

1. Due to the special environment of underground garages (inadequate oxygen supply), a large amount of smoke and carbon monoxide (CO) will be generated in the early stage of a fire. If the induction fans start working at this time, the consequences can be imagined. Therefore, simply detecting CO concentration as the startup indicator is inaccurate, because CO is not only produced by vehicle exhaust. Smoke indicators must be added.

2. It is obviously uneconomical to activate the entire system upon the first detection of excessive CO. Therefore, the program is set such that when excessive CO is detected for the first time, only 1 nearby fan needs to be activated for dilution. The entire garage space also has sufficient capacity to accommodate localized pollution.

3. When the same fan has been working for the set dilution time and CO remains excessive, the program reasonably assumes that the entire garage has reached saturation, and the entire ventilation system must be activated.

4. After the entire induction system is activated, it only forms an airflow field within the garage, conveying air to the exhaust outlets along the designed route. The exhaust fans in the exhaust shafts must be activated to discharge air outward, so interlocking with the exhaust fans is necessary. Similarly, in safe zones, supply fans should be interlocked to supplement fresh air.