Product Specifications

Uses: Used to protect the circuit and the fan from overload and short circuit.

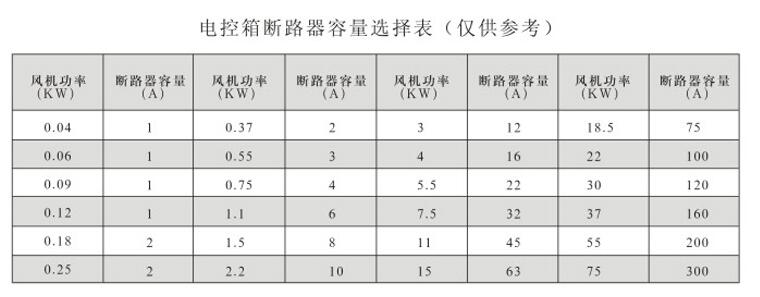

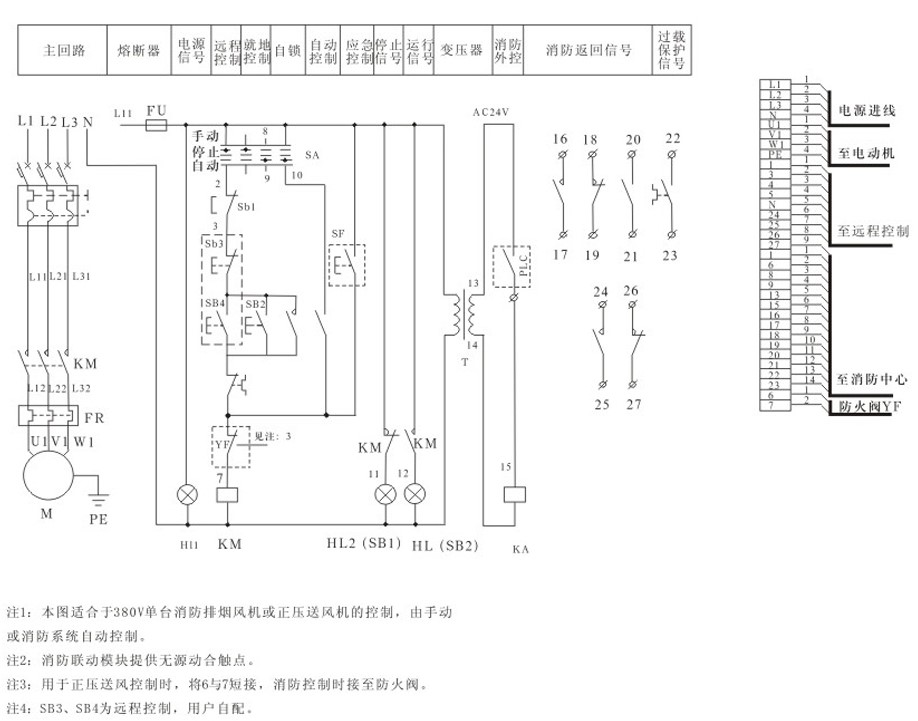

Working principle: The power supply of this electrical control box adopts three-phase five-wire system. The three-phase power supply can enter from the top or bottom, and is connected to the terminal block at the bottom of the electrical control box. The installed automatic air switch QF serves as the short-circuit protection for the dual-speed fan, and the thermal relay FR is used for low-speed overload protection.

Product Overview

1.1. The control box supporting FQ-type fans is mainly used for the normal operation control of various fans produced by our company. It is an accessory of the fan, and users should indicate whether they need to purchase it when placing an order.

1.2. When ordering, users should specify the power of the supporting fan, starting mode, fire protection interface, BA interface, and the brand of main components.

1.3. The control principle of the fan can refer to the national standard atlas 99D303-2 Common Motor Control Circuit Diagrams, with the atlas number specified. It can also adopt the control principle recommended by our company, as detailed in 4.5 and 4.6 Control Schematic Diagrams of FQ-type Fan Special Electrical Control Boxes.

Product Parameters and Description

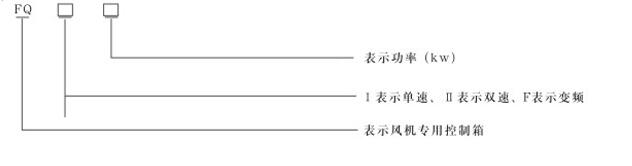

Single-speed control box: The fan runs at only one rotational speed.

Dual-speed control box: The fan adopts pole-changing speed regulation, with low-speed and high-speed modes.

Frequency conversion control box: For frequency conversion fans, using a frequency converter for speed regulation. The recommended frequency range is locked at 25HZ–50HZ.

2. Classification by Starting Mode

Direct starting: Suitable for low-power single-speed fans (generally recommended for power less than 18.5kW).

Star-delta starting: Suitable for high-power single-speed fans (generally recommended for power ≥ 18.5kW).

Soft starting: Suitable for high-power fans.

Autotransformer step-down starting: Suitable for high-power fans.

Frequency conversion starting: Suitable for frequency conversion fans.

3. Naming

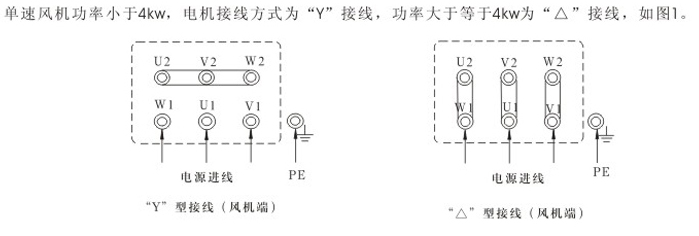

1. Single-speed fan

2. Dual-speed

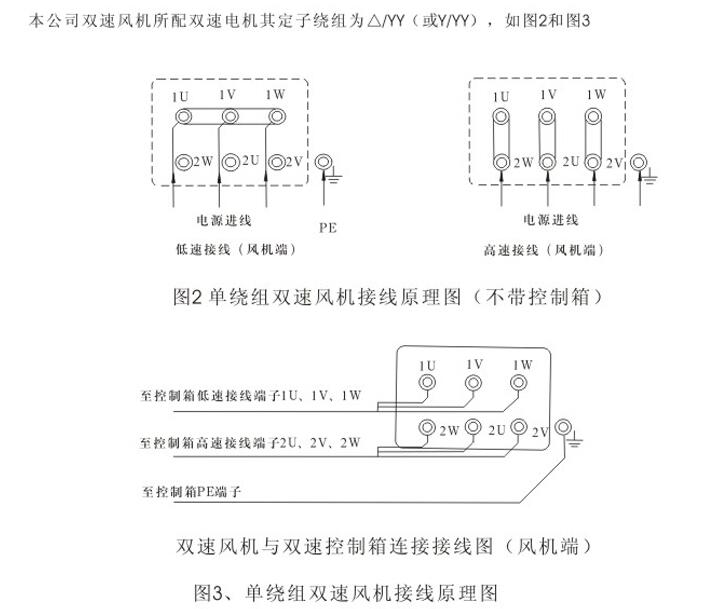

The dual-speed motor matched with the dual-speed fan of our company has a stator winding connected in the O/YY (or Y/YY) configuration. The basic speed regulation principle is to change the connection mode of the motor stator windings, so as to alter the number of pole pairs and achieve the purpose of speed regulation. During low-speed operation, it adopts the △ (or Y) connection mode, while during high-speed operation, it uses the YY connection mode. The circuit breakers, protection devices, and other electrical components equipped in the fan electrical control box must be correctly and reasonably selected according to the rated capacity of the fan.

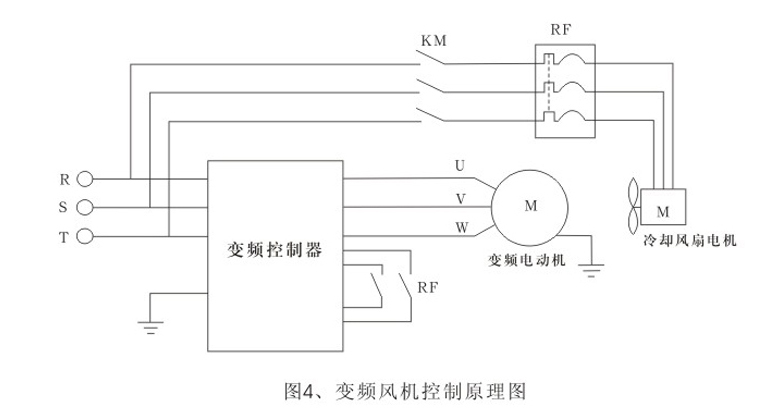

The frequency conversion fan produced by our company is equipped with a frequency conversion motor composed of a main motor and a cooling fan motor. The cooling motor is mainly used for heat dissipation of the main motor and does not have frequency conversion function. Therefore, it must be independently controlled by a set of controllers, with control requirements interlocked with the main motor, meaning the main motor and cooling motor start and stop simultaneously. When the cooling motor fails, the main motor must automatically stop. It is not allowed to connect the cooling fan motor in parallel with the frequency conversion motor, as the cooling fan motor is not a frequency conversion motor—otherwise, it will easily cause damage to the cooling fan motor. Since frequency conversion motors have become popular and are conventional products, the existence of the cooling fan motor should be considered when designing and manufacturing the electrical control box.