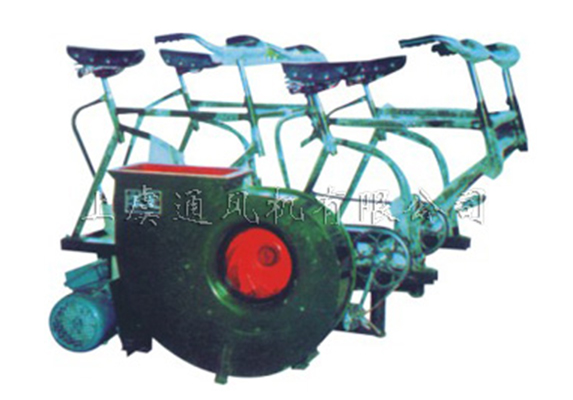

Product Specifications

Features: High efficiency and strong reliability. When the power supply is cut off, the fan can be ventilated by manual operation.

Uses: For ventilation in civil air defense projects, air defense basements, underground hotels, restaurants, shopping malls, etc. It is an essential ventilation equipment for civil air defense projects and basements at all levels.

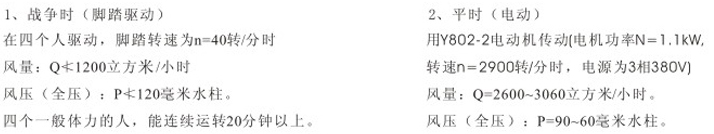

Specifications:

Air volume: 900~3060m³/h,

Wind pressure: 600~2000Pa

Product Overview

Product Parameters and Description

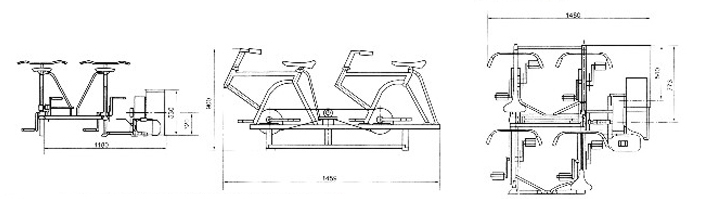

The entire equipment consists of two parts: a centrifugal ventilator and a transmission frame.

The fan mainly includes a volute and an impeller. The impeller is composed of 12 thin-plate arc blades (backward type), a streamlined front disc, a flat rear disc, and a shaft disc. The impeller has undergone static and dynamic balance checks, ensuring stable operation and good aerodynamic performance. It features high efficiency, low noise, and low energy consumption. The fan is designed as left-handed, with the volute-type outlet air direction at 90 degrees; if required, it can also be manufactured with a right-handed 90-degree structure.

The frame is composed of a gearbox, sprocket, saddle, and handle (see the outline diagram for the structure). The transmission components are manufactured with high precision to achieve high mechanical efficiency. The conversion between electric and pedal operation is realized by shifting the handle of the gearbox.

The regular operation mode of the electric-pedal dual-use fan is electric, and pedal operation is only used in wartime. However, once put into use, it is in an emergency situation, so it is crucial to ensure the fan runs reliably. Therefore, daily maintenance should be strengthened, especially for various moving parts. The maintenance work is as follows:

Open the gearbox cover to check the lubricating oil. If the oil has deteriorated, drain it completely and add new No. 120 machine oil. If the oil level is insufficient, add oil until it is flush with the lower surface of the shaft. Then, have one person operate it at a slow speed to check for any jams or knocking sounds. If there are no faults, four people should operate it simultaneously for 5 minutes. If faults are found, repair or replace the parts.

The above maintenance work should be carried out once every three months (once a month in hot and humid weather).