Product Specifications

Features: The volume is manufactured according to user requirements. It features light weight, simple structure, and is convenient for processing, installation and maintenance.

Uses: It is a device used to reduce noise for fans and meet environmental protection requirements, which can effectively block and weaken the propagation of sound energy in all directions.

Specifications: It is manufactured in accordance with national standards and user requirements.

Product Overview

It should have good noise reduction characteristics. Under working environments with certain airflow velocity, temperature, humidity, pressure, etc., it should have a sufficiently large noise reduction amount within the required frequency range, or meet the noise reduction needs within a wide frequency range.

The muffler should have low resistance to airflow, with a low resistance coefficient, and the regenerative noise generated by the airflow passing through the muffler should be low. The muffler should not affect the normal operation of aerodynamic equipment.

The muffler should be small in volume, light in weight, simple in structure, and convenient for processing, installation, and maintenance.

The muffler should have a beautiful and generous appearance, and its volume and shape should meet the constraints of the overall equipment layout.

The muffler should be inexpensive and have a long service life. When selecting, comprehensive analysis and evaluation should be carried out to coordinate various requirements and determine the scheme.

The muffler should be firmly installed on the equipment or pipeline that requires noise reduction. For mufflers with 较大 (relatively large) weight, they should be supported on a special load-bearing frame, and attention should be paid to the strength and rigidity of the support frame.

Noise radiated by the casing or pipeline of the noise reduction equipment may enter the rear end of the muffler, reducing the noise reduction effect. When necessary, sound insulation treatment can be performed on the muffler casing or part of the pipeline. In the air conditioning system, the muffler should be installed as close as possible to the room in use, and the exhaust muffler should be installed in the airflow-balanced pipe section as much as possible.

When the muffler is used outdoors, a rainproof cover should be added; in dusty places, a filter should be added. For general ventilation mufflers, the dust content of the gas passing through should be lower than 150 mg/m³ (note: the original "150mm/m³" is corrected to the standard unit "mg/m³"). It is not allowed for water mist, oil pollution, or corrosive gases to pass through.

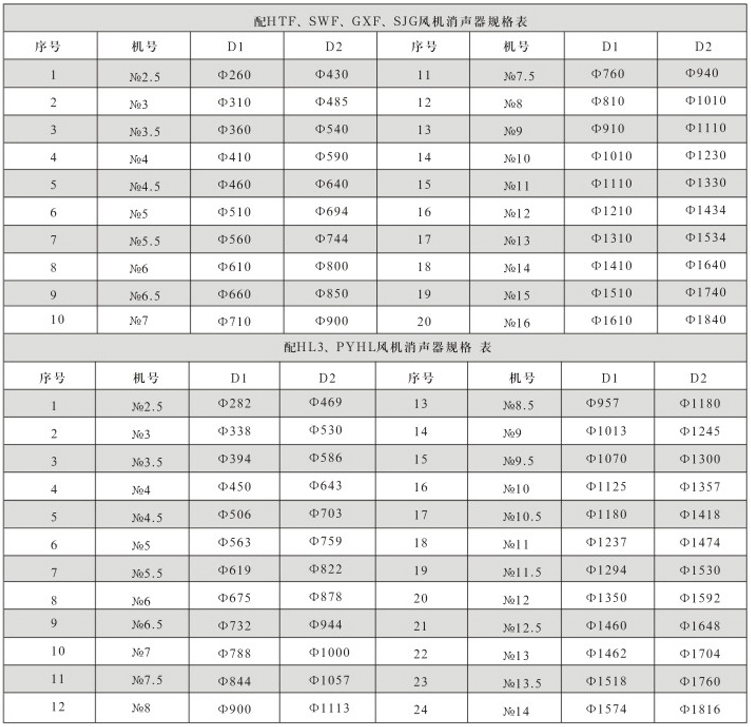

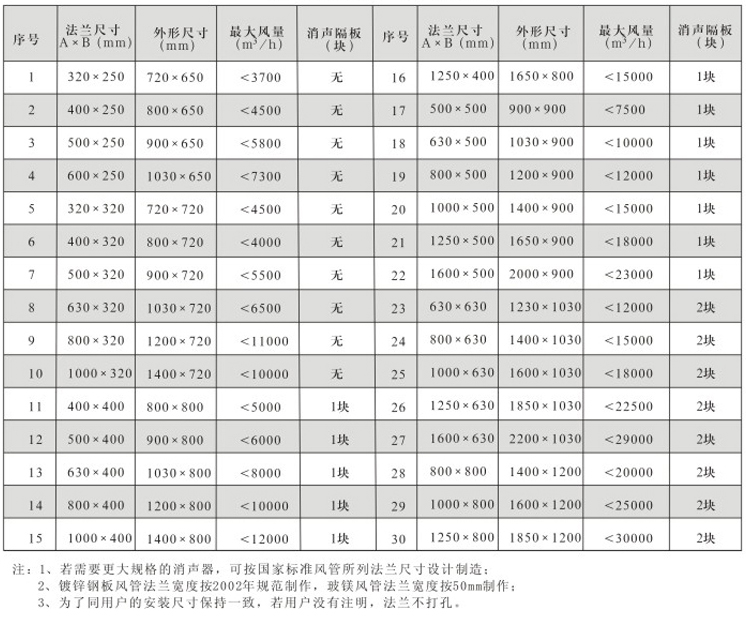

Product Parameters and Description

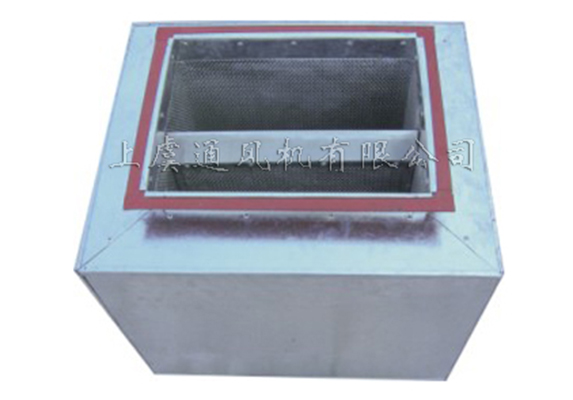

The ZP100 type muffler is a relatively new noise reduction product, mainly used for noise control in various ventilation and air conditioning systems, which can effectively reduce aerodynamic noise. It features a wide applicable air volume range, a full series of specifications, good compatibility with standard air ducts, high noise reduction amount, low airflow resistance, and characteristics such as fireproof, moisture-proof, mildew-proof, and moth-proof. It is particularly suitable for noise reduction in ventilation and air conditioning systems of various large public buildings, such as broadcasting and television buildings, cinemas, conference halls, hotels, restaurants, shopping malls, office buildings, high-end residences, etc., and is also applicable to noise reduction in ventilation and air conditioning systems of factories and enterprises.

The ZP100 type muffler series has a total of 49 different specifications, suitable for air volumes of 720-90000 m³/h, with a noise reduction amount of 15 dB(A)/m and a pressure loss of 14-55 Pa. The noise reduction plates of the ZP100 type muffler are 100 mm thick, and the effective length of a single section is 1000 mm. According to the noise reduction requirements and different on-site installation positions, multiple sections of mufflers can be connected in series for use.

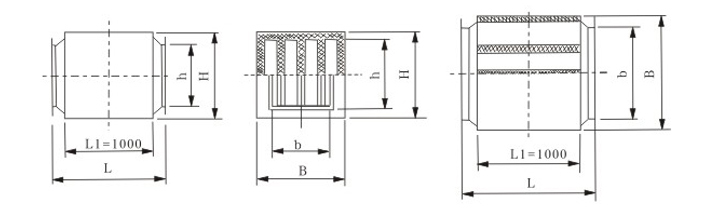

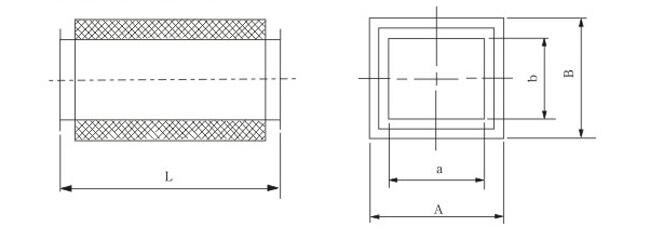

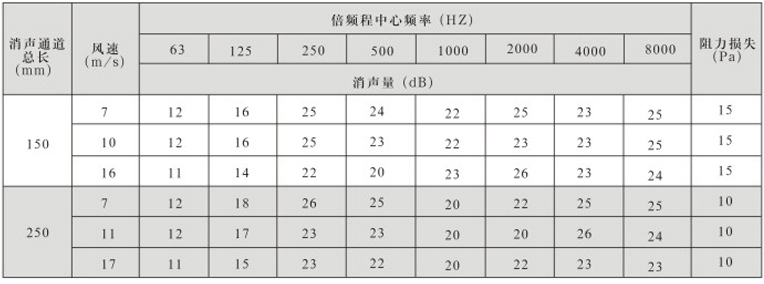

The ZG-type resistive tubular muffler is generally installed at the inlet and outlet of fans to reduce noise generated during fan operation. As a resistive muffler, it is available in two types: circular and square. The inner wall is made of galvanized perforated plates, with an interlayer filled with ultra-fine glass wool as the sound-absorbing material, and the surface layer is glass fiber cloth. The galvanized perforated plates form resistive sound-absorbing sheets. This product features low airflow resistance and excellent sound absorption performance. When the cross-section of the square muffler is ≥630×630 mm, resistive sound-absorbing sheets should be appropriately added.

Note: The length of the muffler can be manufactured according to user requirements. When placing an order, it is necessary to specify whether it is the total length or the effective length.

Note: The length L of the muffler can be manufactured according to user requirements.

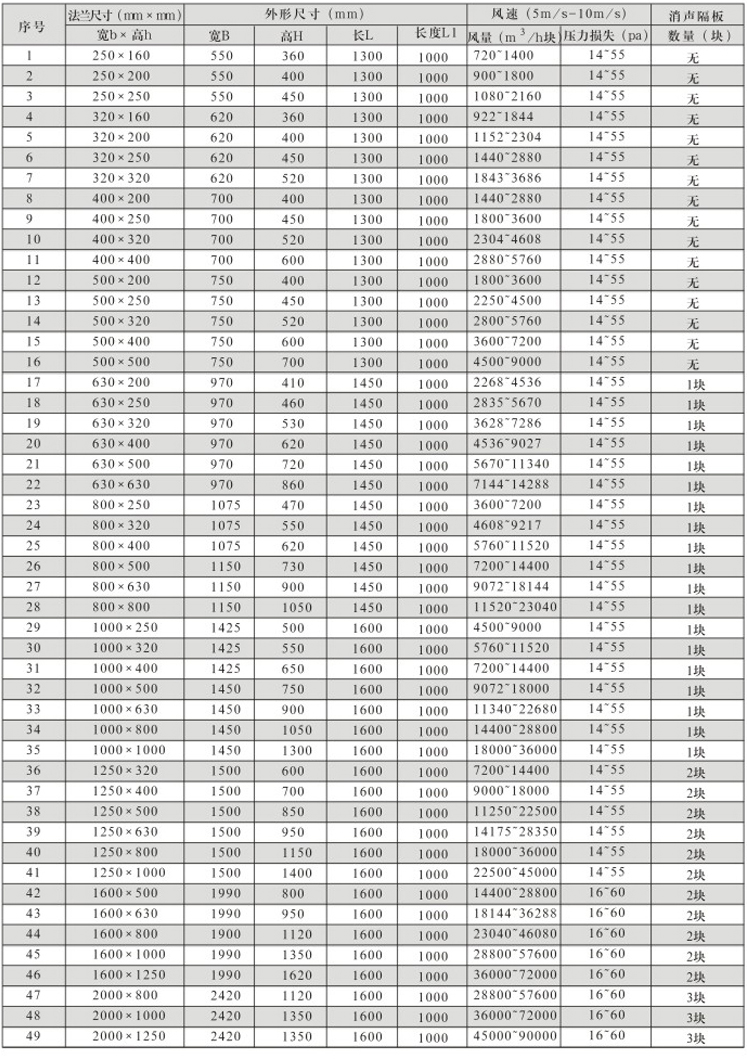

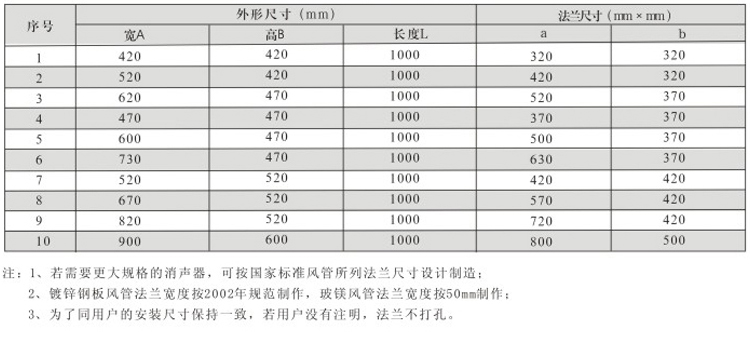

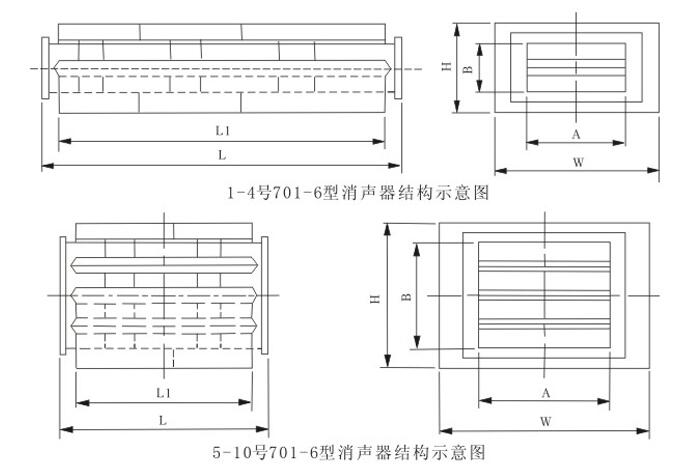

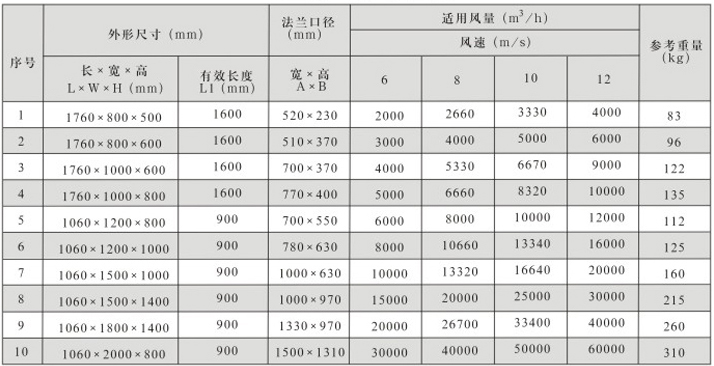

The T701-6 muffler is an impedance composite muffler. Resistive noise reduction is achieved by sound-absorbing sheets with a framework filled with ultra-fine glass wool as the sound-absorbing material; reactive noise reduction is realized through the abrupt change (discontinuity) of the inner pipe cross-section and the expansion chamber between the inner and outer pipes. The muffler casing is rectangular.

This series of mufflers has a total of 10 specifications. Among them, No.1-4 each have a length of 1600 mm, with three expansion chambers in series; No.5-10 each have a length of 900 mm, with two expansion chambers in series. It is suitable for air volumes of 2000-60000 m³/h, air speeds of 6-12 m/s, low-frequency noise reduction of 10-15 dB/m, medium-frequency noise reduction of 15-25 dB/m, and high-frequency noise reduction of 25-30 dB/m.

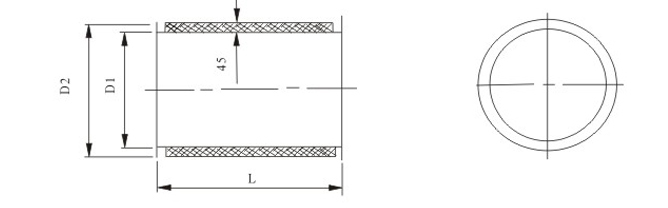

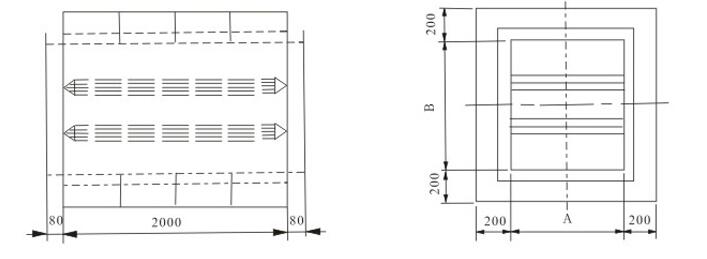

The WX-type microperforated panel muffler features a dual-chamber structure, with a wide absorption frequency band. It shows relatively flat noise reduction across all frequency bands and has a large noise reduction amount, especially with remarkable noise reduction effect on the low-frequency part, which is superior to the impedance composite muffler using fibrous sound-absorbing materials.

The flange diameter of the connecting pipe of this series of mufflers is configured according to the national general ventilation duct specifications (square, rectangular, circular) to form corresponding supporting series. The effective length is generally 2000 mm, and it can also be produced according to user requirements. As per the noise reduction requirements, multiple sections can be connected in series in the middle. The airflow velocity of the muffler is generally ≤15 m/s.

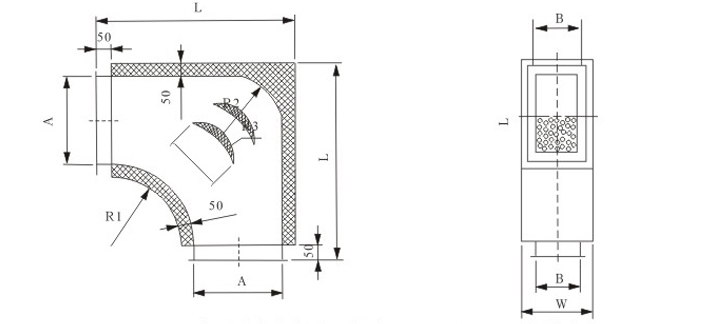

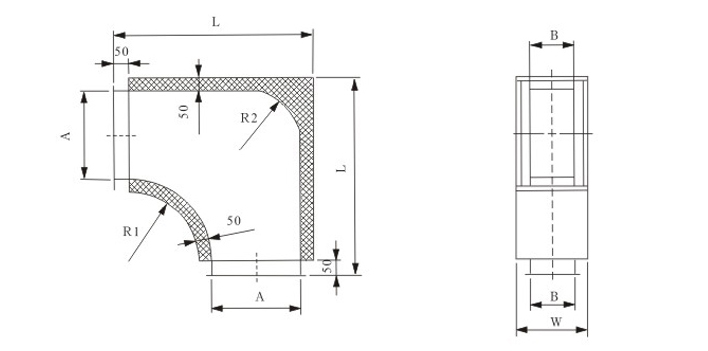

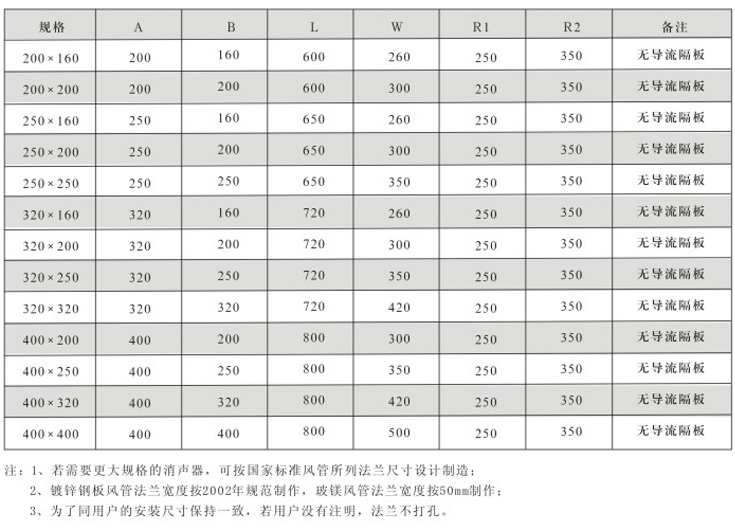

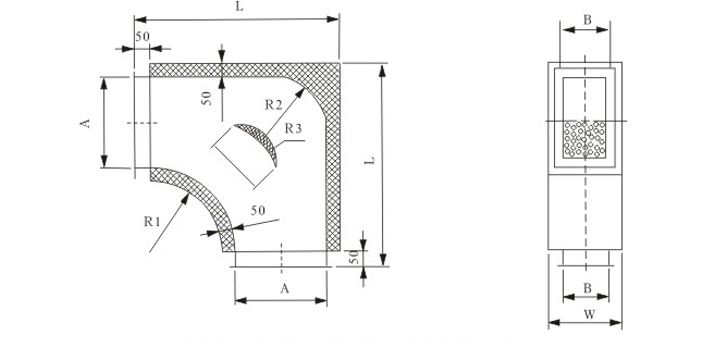

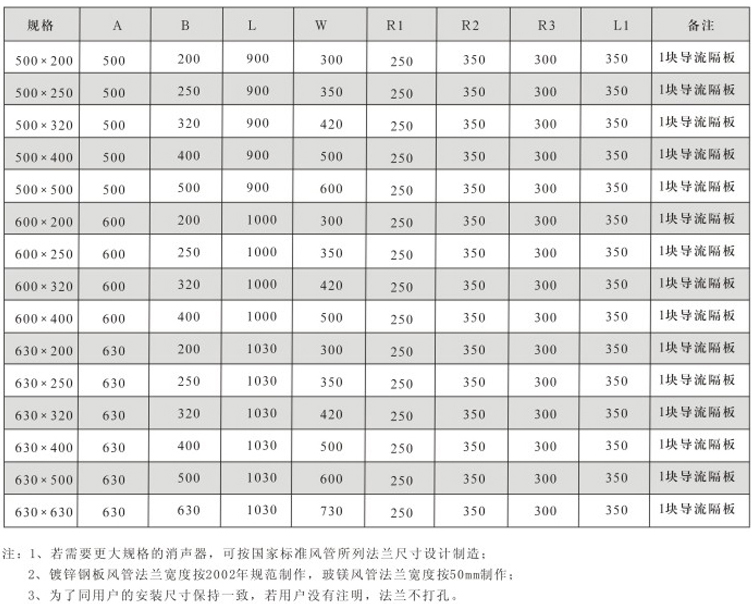

Using a muffling elbow is a simple and effective noise reduction measure. It can not only change the propagation direction of air but also make the layout of fans and air ducts more flexible and reasonable. Muffling elbows can be installed horizontally or vertically. For larger elbows, guide vanes are added. On the premise of ensuring aerodynamic performance, the duct is formed into a right-angle inner arc muffling elbow. The muffling elbow is mainly suitable for noise control in various ventilation and air conditioning systems, featuring a wide applicable air volume range, a full series of specifications, compatibility with standard air ducts, excellent noise reduction performance, low airflow resistance, and convenient installation.

2. Horizontal Muffling Elbow (Long Side: 500-630 mm)

3. Horizontal Muffling Elbow (Long Side: 700-1000 mm) (For sizes above 1000 mm, follow the same logic)