Product Specifications

Features: In the design and manufacturing process, the special conditions required for marine use are taken into consideration. The impeller has undergone strict dynamic balance correction and overspeed testing. This fan features excellent corrosion resistance, resistance to sway and impact vibration, as well as stable operation and safety reliability.

Uses: It is a typical energy-saving and environment-friendly ideal product for ships, with large pressure, high efficiency, low noise and stable operation, which can meet the marine conditions.

Specifications:

Ventilator diameter: Φ265~630mm,

Air volume: 2400~25500m³/h,

Wind pressure: 350~3000Pa

Product Overview

The BT35 series marine axial flow ventilators are new-type energy-saving and environment-friendly ideal products for ships, featuring high pressure, high efficiency, low noise, stable operation, and full compliance with marine conditions. They are suitable for ventilation in various shipboard locations and other compatible scenarios.

The ventilators are designed using the variable circulation method. By selecting reasonable variable circulation coefficients based on the ventilator parameters and rationally distributing the characteristic velocities and lengths across different blade sections, the high circumferential speed at the blade tips is fully utilized. This design endows the ventilators with advantages such as high efficiency, low noise, large flow and pressure coefficients, and light weight.

In the design and manufacturing process, the special requirements for marine use are fully considered: The impellers undergo strict dynamic balance correction and overspeed testing, ensuring the ventilators feature excellent corrosion resistance, impact resistance, sway resistance, vibration resistance, stable operation, and safety reliability.

The impeller is die-cast from aluminum alloy, directly driven by the motor. The casing and support are made of high-quality steel plates and subjected to anti-corrosion treatment. Explosion-proof motors are equipped. The ventilators can be matched with marine AC motors of 380V, 660V, 50Hz or 440V, 60Hz. Meanwhile, according to user needs, the ventilators can be manufactured with two or four air outlets.

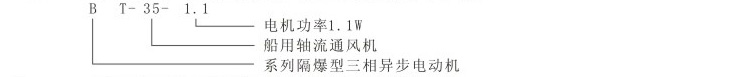

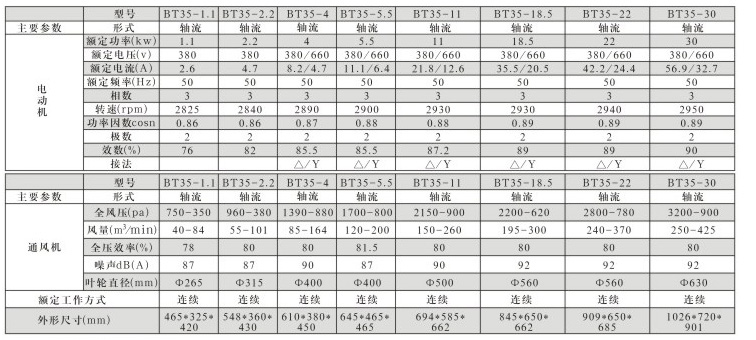

Product Parameters and Description

Specifications, Models and Performance of BT35 Series Marine Vertical Explosion-proof Axial Flow Fans

1. The base of this series of fans is equipped with rubber shock-absorbing pads or pulleys, and the body is equipped with lifting rings, ensuring convenient movement during use.

2. Before use, strictly check the clearance between the impeller and the outer casing. The clearances around the impeller should be uniform, and the wheel should rotate flexibly without jamming.

3. The rotation direction of the impeller must be consistent with the direction indicated by the arrow on the casing.

4. The fan must be managed and operated by a dedicated person.

5. The installation and use of the fan must comply with the relevant regulations of the Safety Regulations.

6. For fans that have undergone long-distance transportation or been left unused for a long time, the insulation resistance of the motor stator must be measured before use (the insulation resistance shall not be less than 0.5 megohm). After passing the inspection, connect to the required power supply, run a trial operation for about 10 minutes, and put it into normal operation if no abnormal noise occurs.

7. The length of the stripped and exposed section at the connection of the motor lead wire joint shall not exceed 1.5mm.

8. Use the largest diameter adhesive cloth air duct allowed by the tunnel cross-section as much as possible. Each section should be as long as possible, laid as straight as possible, with no wrinkles on the duct wall. The direction at the bend should be changed gradually to reduce pipeline resistance loss and ensure the air supply distance. The diameter of the air duct used is generally not smaller than the outlet diameter of the fan.