Product Specifications

Features: All aluminum shell, anti-corrosion, light weight, low noise, high efficiency, beautiful appearance, stable operation.

Uses: Roof ventilation and firefighting of large factories, high temperature smoke exhaust, etc.

Specifications:

Ventilator diameter: Φ300~1000mm,

Air volume: 1335~55215m³/h,

Wind pressure: 30~650Pa

Product Overview

The impellers and motor sizes of this series of fans are divided into 8 specifications according to the impeller diameter: 300, 425, 500, 575, 675, 750, 900, and 1000. The air volume ranges from 1275 m³/h to 55215 m³/h, and the maximum static pressure reaches 650 Pa.

Product Features

1. Fan Impeller: High and low-pressure aluminum alloy impellers optimized through advanced technology. The front disc, rear disc, and blades of the impeller are processed via multiple procedures such as stamping blanking and die pressing, featuring a compact structure with large air volume, low noise, and high efficiency.

2. Supporting Motor: Motors with protection class IP54 and insulation class F are used. If equipped with H-class insulation, the product can continuously operate in a high-temperature environment of 300℃ for 45 minutes. Explosion-proof motors, dual-speed motors, and frequency conversion motors are also available.

3. Housing: The overall structural strength of the fan is designed to withstand extreme outdoor wind speeds of 50m/s. Made of aluminum alloy and processed by stretching and flanging, the housing ensures sufficient strength while enhancing aesthetic appearance, reducing self-weight, lowering the strength requirements for roof foundations, and demonstrating excellent wind resistance.

4. Wind Cowl: Manufactured from aluminum alloy, integrally stretched and flanged. With patented technology, it features light weight, high strength, and low wind resistance.

5. Collector: Made of high-quality aluminum alloy using a one-time forming process, ensuring the impeller guide port fully matches the air inlet. The hyperbolic air inlet conforming to fluid mechanics effectively controls airflow organization, significantly reducing inlet noise and improving fan efficiency.

6. Fixed Bracket: Cut and formed by CNC, with fixing holes processed by multi-station CNC punching machines for convenient installation.

7. Drive Device: This series of fans adopts two forms: belt drive and direct connection.

8. Air Valve: Available in gravity automatic closing type or electric drive opening/closing type. The gravity automatic closing air valve has a hot-dip galvanized steel frame and aluminum alloy shutters; the electric drive opening/closing air valve uses aluminum alloy insulated shutters to prevent condensation and backflow, especially suitable for cold regions in the north. It can be used for both smoke exhaust and ventilation, and smoke fire dampers can be optionally configured. Both the fan and smoke fire damper have passed the national fire product type test.

9. Installation and Maintenance: The motor protective cover adopts a buckle fixing structure, which is easy to operate, saving time and effort.

10. Stable Operation: The fan has a small moment of inertia and excellent balance quality, reaching the G2.5 balance quality level of ISO1940 standard. It undergoes mechanical operation tests, vibration tests, and aerodynamic performance tests to ensure stable and reliable operation, effectively extending service life, reducing noise, and minimizing vibration.

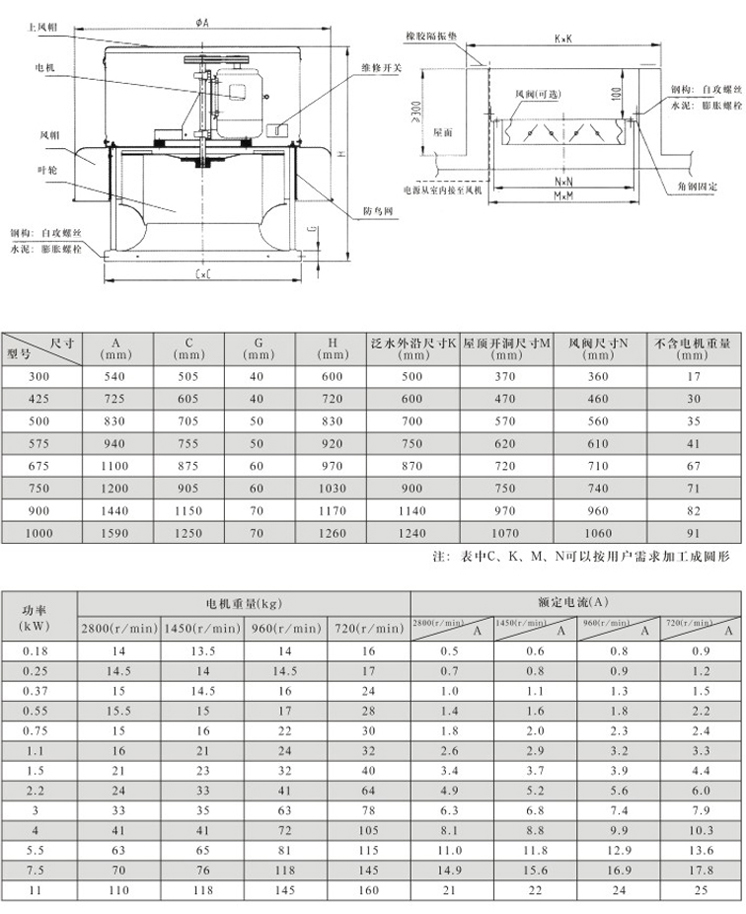

The outline structure diagram and installation dimensions of RTC series fans

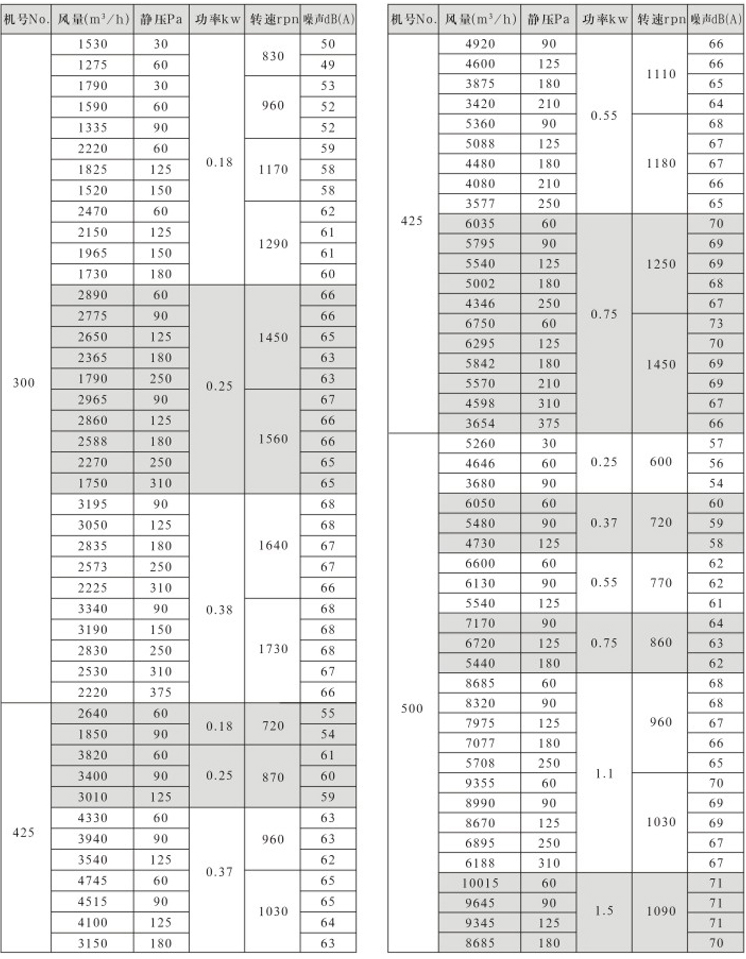

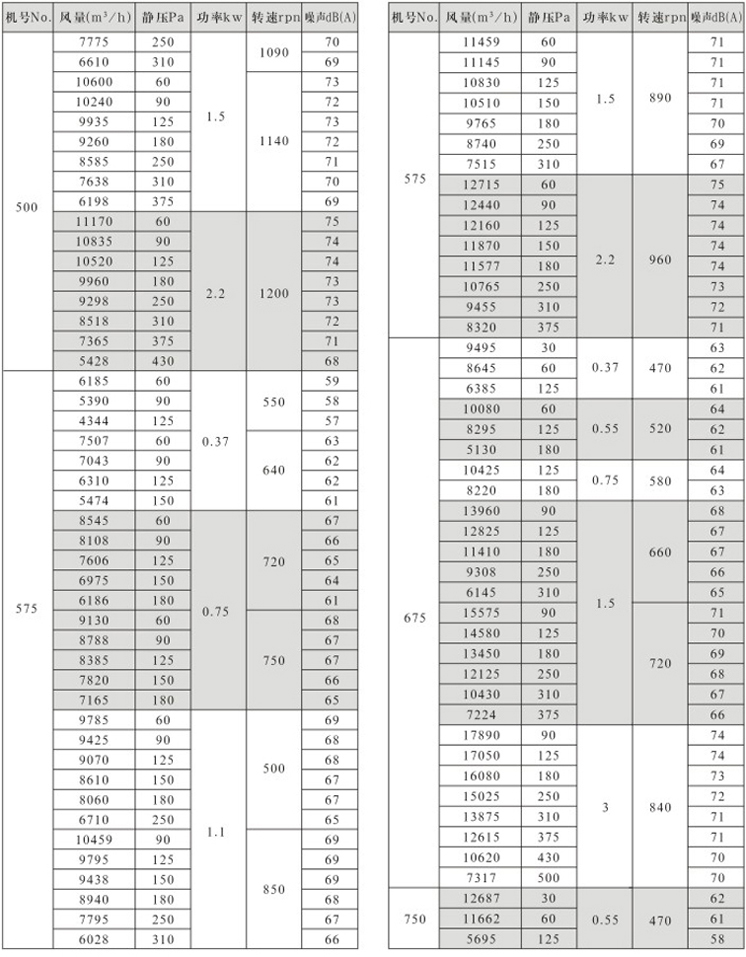

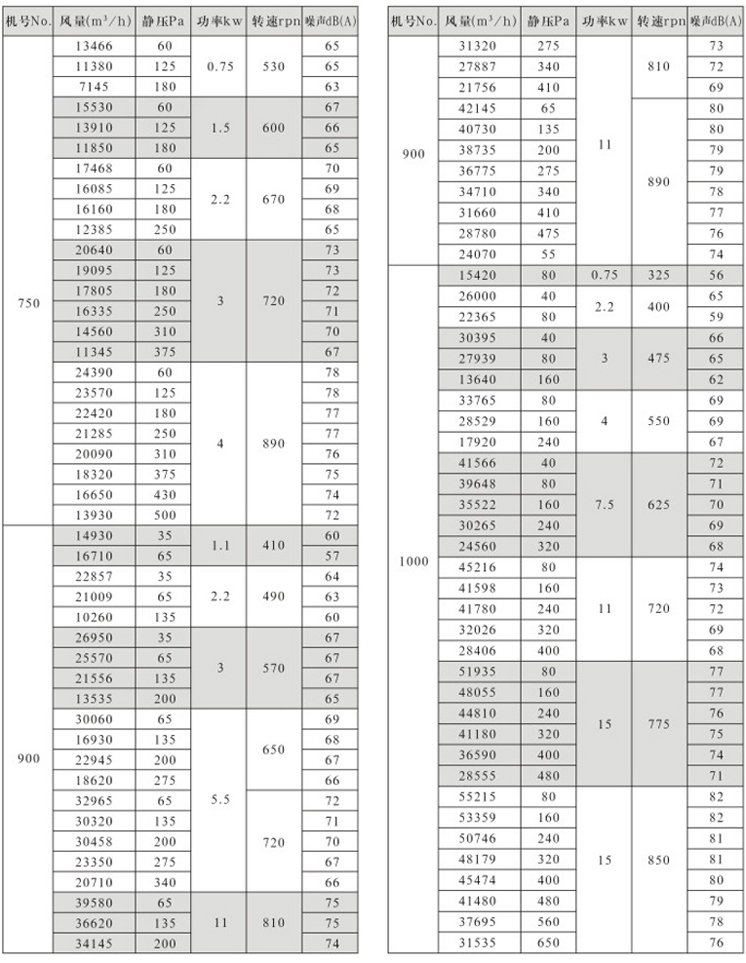

Performance Parameters Table of RTC Series Low-Noise Centrifugal Roof Exhaust Fans