Product Specifications

Features: It is suitable for industries such as power plants and textiles, with extremely wide applications. However, it generally has the disadvantages of parameter mismatch, high energy consumption, and high noise. Therefore, our factory has developed an adjustable blade angle air-conditioning fan by adopting the design methods of large chord length, inclined blade profile, low rotational speed, and high pressure coefficient. It has been proved by the use of various factories and mines that the operation effect is good, the noise is reduced by more than 10dB(A), the energy is saved by more than 20%, and the total pressure efficiency is greater than 80%. Therefore, it has the characteristics of low noise, energy saving, and reliability.

Uses: Power plants, textiles and other industries

Specifications:

Ventilator diameter: Φ800~240mm,

Air volume: 25000~200000m³/h,

Wind pressure: 350~500Pa

Product Overview

In industries such as power stations and textiles, various large axial fans are widely used, but they generally suffer from mismatched performance parameters, leading to high power consumption and noise. To save energy and reduce noise, Shangyu Ventilator has collaborated with Shanghai Jiao Tong University to develop the DFZ large air-conditioning fan. Field performance tests conducted by multiple units have shown good operation results: the noise is 10dB(A) lower than that of old models, energy consumption is saved by more than 20%, the fan efficiency is over 80%, and the effic

Product Parameters and Description

Technical Parameters

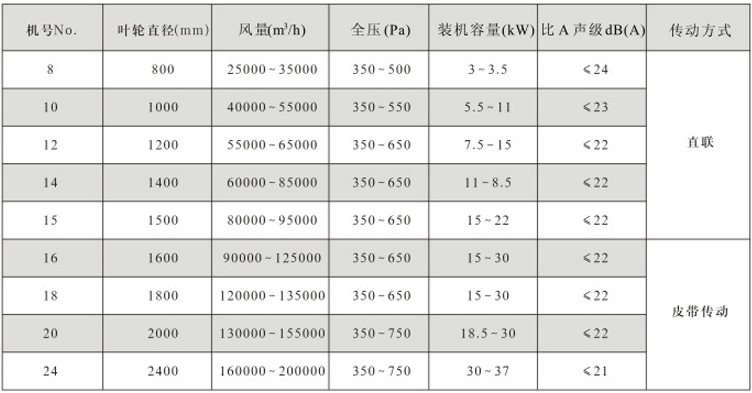

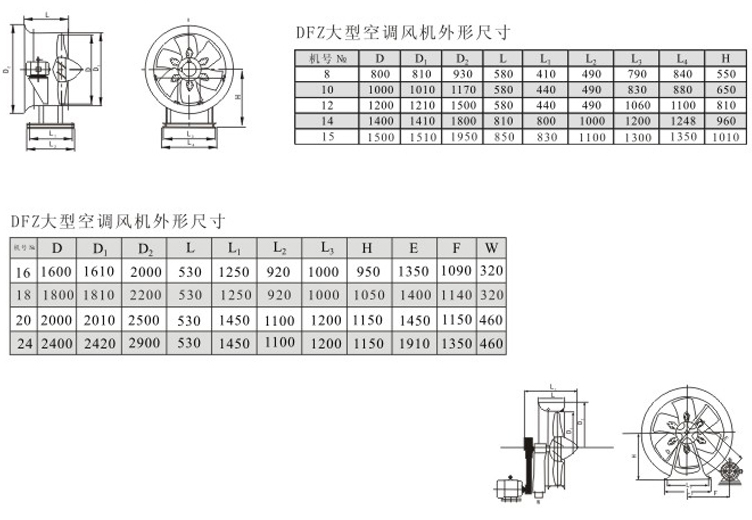

The fans of this series are available in nine specifications from No.8 to No.24, with multiple varieties. The air volume ranges from 25,000 m³/h to 200,000 m³/h, and the air pressure is 350-750 Pa. Users can make selections based on the performance parameter table or actual usage conditions.

DFZ Large Axial Flow Fan

The Selection of DFZ Fans

Reasonable selection is the key to saving energy and reducing noise. If the selection is improper and the parameters do not match, the fan will not operate within the optimal working conditions, resulting in reduced air volume, decreased operating efficiency, and increased noise. Therefore, to ensure the service life of the product, users can make reasonable selections according to different usage conditions with reference to the performance curves.

Operation and Maintenance of DFZ Fans

1. Before starting the fan, first check whether there are any objects around the fan that may hinder its rotation, and inspect whether the installation angles of the blades are consistent.

2. Check whether the insulation performance of the motor is good, and look for any friction or collision. Ensure that the fastening screws in all parts are not loose. Connect to the power supply and run for one hour, then stop to check if the motor heating is normal. Put it into operation only after everything is normal.

3. During operation, monitor the ammeter to check if the motor is overloaded. If so, stop the machine immediately for inspection.

4. After the fan has been in operation for half a year, lubricating oil should be added to the bearing box to extend the service life of the bearings and main shaft.

1. Minimize pipeline network resistance, and reasonably select the pipeline size and installation location.

2. Control the radial clearance value between the air duct and the blade tips.

3. Reasonably select the fan model to achieve device matching, and prevent the fan from operating in the low-efficiency zone.

4. Ensure matching with the installed capacity to avoid "using a large horse to pull a small cart" (i.e., overcapacity causing inefficiency).

5. Adopt stepless speed regulation devices or dual-speed motors.